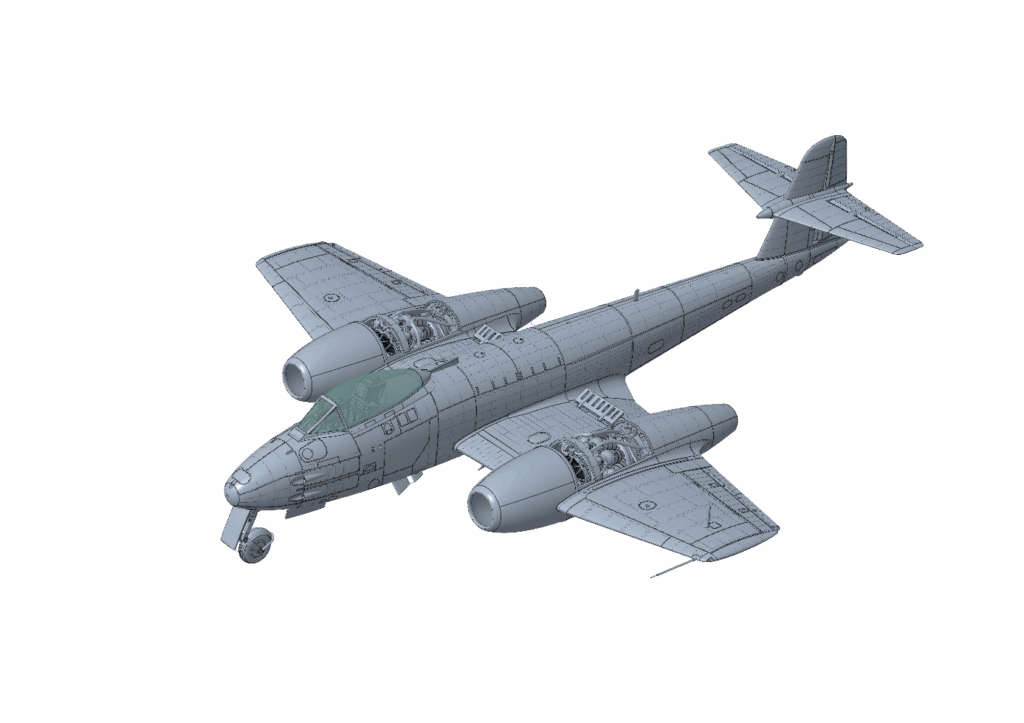

The upcoming release of Revell’s 1:32 Gloster Meteor F.8/FR.9 is generating major excitement in the scale modeling community and for good reason. Not only does this kit bring a legendary jet to life in a new, highly detailed format, but it also showcases some fascinating developments in modern model kit production. Thanks to a recent conversation with Luke who is the product manager on our team, we now have a behind-the-scenes look at the tooling and manufacturing process, offering insights that will intrigue both modelers and aviation enthusiasts.

A New Era for the Meteor in 1:32 Scale

Revell’s decision to focus on the F.8/FR.9 variant for this release was a direct response to community feedback. While the project originally began as an F.3, market demand made it clear that the F.8/FR.9 was the version most wanted by modelers. The result: a completely new tooling, packed with options and details.

Luke’s insights from the tooling shop

Luke’s insights from the tooling shop

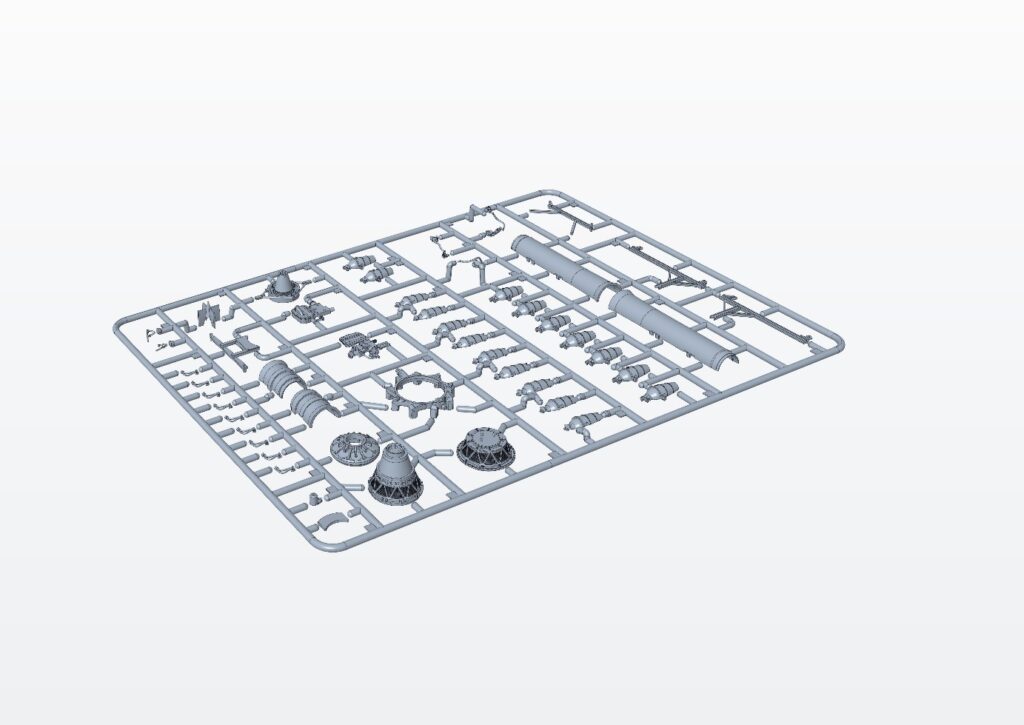

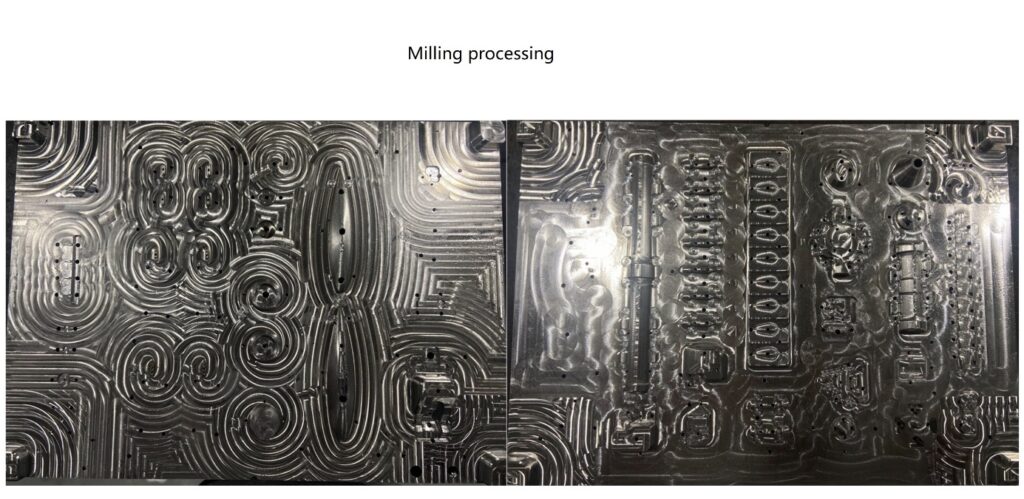

The Meteor’s twin-engine configuration presented a unique challenge. Instead of cutting two identical sets of engine parts into the steel mold, our team opted for a “double run” approach. They cut the engine parts once and run the mold twice for each kit. This reduces upfront tooling costs and streamlines production, though it means each mold will experience double the cycles for this part. Still, these molds are rated for hundreds of thousands of cycles—far beyond what’s needed for a limited run.

Luke and the team paid special attention to how parts are grouped on the sprues. For the Meteor’s engines, all components are kept on a single frame. This makes assembly more intuitive and minimizes frustration for builders, especially with a kit containing over 250 parts. It also opens the door for potential future releases of the Meteor’s Rolls Royce Derwent engine as a standalone kit.

While the molds are insured for up to half a million cycles, actual production volumes will be much lower. The team monitors tool wear closely—if a kit proves popular enough to approach the tool’s lifespan, it’s often more economical to retool than to keep repairing the original mold.

While the molds are insured for up to half a million cycles, actual production volumes will be much lower. The team monitors tool wear closely—if a kit proves popular enough to approach the tool’s lifespan, it’s often more economical to retool than to keep repairing the original mold.

After the steel is cut, the factory produces “test shots”—initial plastic runs sent to the design team for review. It’s common to go through three or four rounds of test shots, with dozens of comments and corrections each time. This iterative process ensures that fit, detail, and part placement meet Revell’s high standards before mass production begins.

Production Timeline and Logistics

Production Timeline and Logistics

We don’t want to jinx it but: The Meteor F.8/FR.9 is on track for a November release. As of the latest update, steel cutting is underway, and the first test shots are expected within a month. After several rounds of feedback and refinement, the kits will be shipped from China to Revell’s facilities in Germany and Poland for final packaging and distribution. We plan to announce more details regarding the ‘First Edition’ boxing in June so watch this space!

Historical and Technical Highlights of the Meteor F.8/FR.9

For those who are not (yet) that familiar with the Gloster Meteor we put together some facts about the plane and what makes it so special. No discussion of the Meteor is complete without a nod to its place in aviation history:

- First British Jet Fighter:

The Gloster Meteor was the first British jet fighter and the only Allied jet to see combat in World War II. Its operational debut in 1944 marked the dawn of the jet age. - Modular Construction:

The Meteor was designed for modular assembly, with five main sections built by different subcontractors an approach slightly mirrored in the kit’s own modular sprue layout - The F.8 and FR.9 Variants:

The F.8 was the definitive single-seat fighter version, featuring improved aerodynamics, a new tail design for better stability, and more powerful Rolls Royce Derwent 8 engines. The FR.9 was a photo-reconnaissance variant, equipped with cameras in the nose and additional fuel capacity for longer missions - Legacy:

The Meteor served with air forces around the world and remained in use for decades, including as a trainer and target tug. Its robust design and adaptability made it a favorite among pilots and engineers alike

Revell’s Gloster Meteor is goint to be a Must-Have for Modelers and Aviation Fans

This is the first time the F.8/FR.9 has been offered in 1:32 scale, making it a centerpiece for any collection

Revell’s Gloster Meteor F.8/FR.9 is more than just a model kit. It’s a showcase of modern tooling techniques, thoughtful design, and deep respect for aviation history. Thanks to the insights from our team, we can appreciate not only the finished product but also the innovation and care that go into its creation.

If you’re passionate about classic jets or want to experience the latest in model kit engineering, this Meteor deserves a spot on your workbench.

And of course we keep you posted here about the further production process.

Let us know if you have any questions about the kit. Please email info.de@carrera-revell.com with the subject ‘Gloster Meteor Update’